Production systems for cathode active material

The production of cathode active material for lithium-ion batteries is a complex process that involves several steps from drying, milling and mixing of the raw material or precursors to refining of active material and coating.

ON provides innovative and sustainable battery production technologies for both your anode and cathode active material production process. This includes the planning and manufacturing of lab equipment for product development, pilot plants as well as the scale-up for the industrial production of anode and cathode active materials.

ON's solutions for advanced battery manufacturing encompass processes such as grinding, mixing, drying, and other essential steps. In the high-end industrial sector, the majority of industries rely on our process engineering solutions.

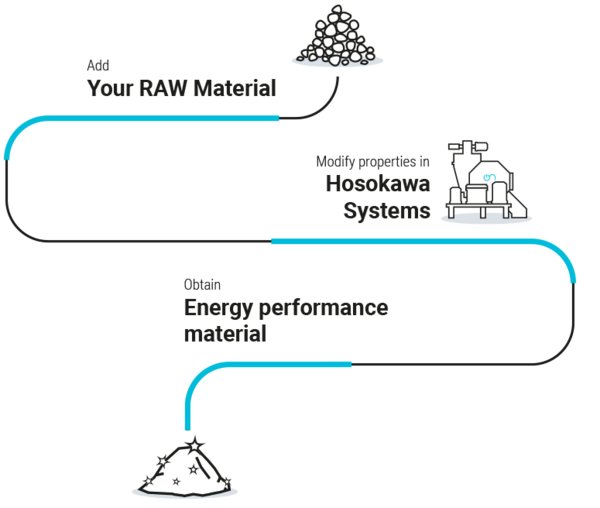

Raw material for battery manufacturing

The graphite-silicon mixtures of the anode and the lithium compounds of the cathode are the most important raw materials for battery production. ON offers a variety of battery production technologies that are used in the production of lithium-ion batteries. Take a look at our solutions for energy performance materials and find out how your batteries can be improved with our lithium-ion battery production equipment!

Battery production systems: Our technology

ON's battery production technology covers the entire process chain for both anode and cathode active materials. In addition, we offer containment solutions to provide maximum protection for your employees and keep your products free from contamination. We are also happy to assist you throughout the entire product development process: from the first trials in our test centres and a pilot plant to scale-up to industrial production.

Containment in battery production

To obtain the best possible end product, the materials for battery production must be absolutely contamination-free. Hosokawa ON’s pragmatic, efficient and tailor-made containment solutions secure your processes from development to production. Find out how you can make your battery production safe with our containment solutions!

Scale-up for battery production systems

Are you a start-up in the growing future market of lithium-ion battery production? And are you looking for the optimal process to develop energy performance materials? ON is your perfect partner for battery production technology! We accompany you from the first test in our test centres to industrial production. Explore how your battery production can benefit from ON's scale-up possibilities!

Equipment for battery production

From grinding to recycling: ON offers a wide range of machines and systems for your battery production. What all our machines and systems for processing active and raw materials for battery production have in common: They are tailor-made to your specific requirements. So you can be sure to obtain the perfect equipment for your product and process.